What Makes Bosch Fuel Injectors Better?

When Snake Eater Performance was graced with the opportunity to collaborate with Bosch’s performance aftermarket division to develop a new line of premium fuel injectors, we were elated. Since then, we’ve launched several dozen genuine Bosch-based fuel injectors for higher performance vehicles and race cars. We cover nearly every application (and for those that we don’t, rest assured we’re working on it). Best of all, we’ve kept our honest profit margins and direct-to-user business model, and we can offer some fantastic prices on all our Bosch based products.

However, we still get a lot of people asking the question, “Why does the Bosch-based stuff cost more?”

As with most products, it comes down to quality. But it’s not so simple as Bosch simply being better. Here’s a closer look as what sets Bosch fuel injectors apart.

The Bosch Difference

There are always certain names in certain industries that are synonymous with quality and leadership. For many industries, Bosch is that name, and the fuel injection components industry is no exception.

Since its founding in 1886 in Stuttgart, Germany, Bosch has grown to become of the top names in engineering and manufacturing. Living up to their motto, “Invented for life,” Bosch engineers and manufactures a product that is not only beneficial to its customers’ daily applications, but also reliable for the entirety of its intended service life.

Working with Bosch has been a truly impressive experience. Pursuing this opportunity was challenging but worthwhile. True to their standards, Bosch requires an in-depth audit. We were required to demonstrate our abilities of high-quality flow matching, data collection, and general manufacturing. The genuine Bosch injectors we choose to use as our base product for the “GB” line of fuel injectors come from the latest generation of fuel injection engineering, well known as EV-14. The EV-14 fuel injector is one of those “under promise, over deliver” products for which Bosch is well known. Its engineering is literally the standard for high performance OEM vehicles. That’s because with little change to the external appearance and internal make-up, this injector is found on everything from small 2-cylinder motorcycle engines to Lamborghinis, all the way up to 1,500 horsepower twin turbo v-8s. There’s no coincidence there; the EV-14 injector is versatile, and with some minor adapting, it is as close to universal fitment as possible.

Aside from their versatility, there are many other, important differences between Bosch-based products and the Chinese-manufactured products. Many of our long-time customers know that Snake Eater Performance started in 2018 providing a simple service: customer service and warranty. Back then, many people were buying random Chinese-made injectors from e-Bay and installing them in hopes of obtaining MASSIVE horsepower for their home-built race cars. The problem was that many of the injectors being sold had no guarantee to work and no guarantee they would be flow matched. Tuning data? Not even on the radar.

That’s where SEP came in. We started modest — no flow match, just a warranty. We wanted to be able to back the budget guys as best as we could. Our goal was to provide a place to get pre- and post-purchase customer service and support for budget injectors. Over time, and as we developed a relationship with the manufacturers, we were able to further develop the quality of the injectors and the services we provide.

We went from three models of injectors to dozens. We also went from having no flow match and no data to precision flow matching, data collection, offset matching — and it’s all done on the best machinery money can buy, with a true lifetime warranty.

With all that in mind, the Chinese injectors still under perform compared to the Bosch-based products (made in the USA and Germany) on many levels. That’s why we saw the value in providing a “premium” line of injectors for people who may have more room in their budget.

The Data Speaks for Itself

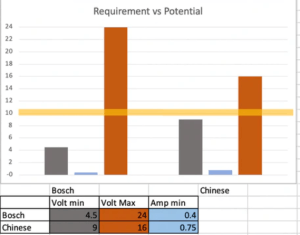

The data we used to create these graphs was generated by SEP using historic averages from actual customer products which were chosen at random. Each table shows eight injectors of the same model which represents products within the full manufacturing interval, defective products aside, to the best of our ability.

THESE ARE NOT FLOW MATCHED SETS or intended to represent the product at retail.

We used an ASNU Classic GDI, advanced control software, and a bench top power supply to regulate power to the injectors.

These are strictly the views and findings of SEP and not that of any of our manufacturing partners, Bosch, or any third party. This information is strictly to demonstrate variations that occur in all manufactured products.

As you can see, the Bosch-manufactured products were significantly closer to the intended mid-line with a 3% flow rate variation and 12% offset manufacturing variance amongst this group of injectors. The Chinese variants were less refined, with an 8% flow and 15% offset manufacturing variance.

Now, if you’re like me, you might think, “So what? Once they’re flow matched, the actual set of injectors will be 2% dynamic flow and 5% offset.” You are correct, they will be and that is excellent but…

The main issue with a wider variance, even with flow matching, comes in at the ECU and tuner level.

The orange line represents the average injector characteristic and where it would be most beneficial to create your injector calibration data. Since injector calibration data is not cheap to generate, you need the most bang for your buck.

You take the average among all injectors and that’s where you make your data. This is a good explanation for why the “sloppy mechanic,” home tuners, and epistemologically sound calibrators seem to have great luck with Chinese-made products, while the fancy pants “CaLiBrAtOrs” claim they can’t get any of them to work (in addition to the monetary incentive of in-person injector sales commission some receive).

When using a product with such deviation from the calibration data, more time and intention is required to make small adjustments. It’s not a simple “reload base tune from a previous, similar client, upload injector data from website, adjust for unique vehicle circumstances, collect money” situation.

Now, there is something to be said for good, repeatable results in manufacturing. We’re not discounting that. It may make your life easier on the dyno and certainly will if you’re a first timer learning to tune on a more complex software such as HPTuners.

If you’re using a standalone ECU, many don’t even have the ability to adjust for finer details, such as short pulse width and have very simple interfaces which limit user input. These are a good situation for the wider flow, offset, and ECU data variations found in Chinese made injectors.

This is why many EFI ECU manufacturers that have their own line of injectors don’t see great successes when used outside their own or other standalone ECUs. Many don’t even bother to flow match their products, or their flow match standards are looser. Their assumed approach is to allow the ECU to learn through trial and error, adding and subtracting fuel to each injector either individually or between banks until a favorable AFR and/or other conditions are met.

Simply put, the standalone ECU is either not capable and/or intended to really care about the finer details. It’s not trying to pass emissions tests or other complex scenarios.

OEM manufacturers of fuel injectors keep their manufacturing standards very tight because the end user is not likely to be flow matching them.

They are most likely to be sold in single units as a means of replacing a faulty or failed injector. That means they need to essentially ensure a flow match regardless of the end users’ ability to access the machinery needed to achieve a flow match.

This makes life very nice when you look at ECU tuning data.

It’s always going to be very close — if the injector data matches the injector installed, you’ll have a much easier time tuning an OEM ECU. This is especially true for more intensive OEM ECUs, which can use injector data for more than a fuel table.

OEM injectors also cost significantly more because they use the highest quality stainless steels to combat corrosion. This is particularly useful for vehicles that sit for long periods of time, such as fleet vehicles or vehicles which may not start or run over winter.

Most Chinese-made fuel injectors use a grade of stainless which cannot withstand the corrosion from alcohol/water mixes as well as the OEM intended injectors. This water/alcohol mixture can form in your gas tank in humid environments or when fuel sits too long and separates — a factor that should also be noted when considering injectors for marine applications.

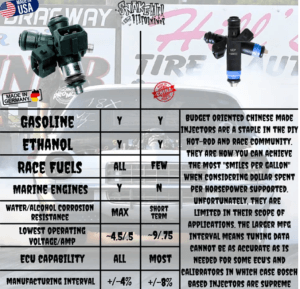

Lowest Operating Voltage/Amperage

You may think an injector probably only needs to operate in a power range that’s very close to your battery or alternator, right? Something like 10-16v sound good? Well, you’re right — but with both OEM and performance/race applications there are many occasions when voltage drops below 10 volts, whether it’s momentarily or for longer periods of time.

We usually see this when people are essentially trying to street drive a race car. The larger displacement engines, higher engine bay temperatures from turbos, superchargers and larger radiators all bring electrical output down. Now, factor in some big fans to go with that nice new oversized radiator, and you’re going to see some voltage drop.

As for OEM applications, we see this in events such as extremely cold starts — for example, instances when the battery is very cold, the fuel is very cold, and the harsh environment taxes the amount of power the ECU can send to the injector driver.

Using our same flow bench setup, we can accurately represent some portions of these scenarios. With the bench power supply and advance control software, we can create a low voltage, cold crank scenario (without the actual temperature) with the actual injector requirement. Cranking is a unique scnario for injectors; it’s low RPM and wide pulse width.

For this test, we set the machine to standard cranking pulse width and RPM requirements, lowered the voltage and amperage to 0, and primed the fuel system to 43psi. We then slowly began to increase the power to the injector driver to determine the minimum operating voltage/amperage that could get all eight injectors to fire consistently and produce repeatable results.

Here are the results:

Here’s how I interpret these results. Both injectors can operate equally as well in a “perfect” scenario. However, look at the orange line: that’s a low-end representation of the average cranking volts displayed on an ECU interface and represents around 9.8-11 volts. Both injectors can fire and crank just fine in this range; however, the Chinese-made injector is very close to its lower limit. Now, if you add in very cold temperatures (VERY COLD, such as negative Fahrenheit temperatures), you may start to see some issues.

The most likely case where I could see you having an issue with these is if you have a lot of accessories that are not switched or constantly drawing power. We’ve had this issue arise with a few customers, and while it’s not the injectors fault, your situation may demand the lower voltage requirements.

As for the premium and OEM capable Bosch injector, it’s nowhere near its requirement limits. That means if you have a fan that could be running during hot starts, water pump, intercooler pump, or other accessories that are not on a switch, you may need to consider the higher priced injector.

One more thing to note: In our experience, some ECUs (both factory and aftermarket) DO NOT like the higher voltage requirement of some Chinese-made injectors. The most common GM ECUs do not seem to have any issue at all, but a few smaller DIY-focused ECUs and older OEM ECUs have had issues. This is especially true if the OEM harness is tapped into for auxiliary power to accessories.

So, Do You Really Need a Bosch Fuel Injector?

Now, don’t let this discourage you. If you’re on a shoestring budget, Chinese injectors with wide manufacturing variations have been used thousands and thousands of times with OEM and aftermarket ECUs and aftermarket calibration software such as HPTuners or EFIlive. Just bear in mind it just may take a little more time behind the wheel or on the rollers to figure out all the fine details. There are plenty of testimonials to this on our Instagram (@snakeeaterperformance).

So, to distill it all down and give you the bottom line, here’s what I think about the two styles of injectors we sell, and who each one is best for.

Bosch-based injector sets: These are well suited for anyone and everyone. They really shine if you’re taking them to a professional tuner (especially if paying by the hour) and want reliability like a daily driver with immaculate low RPM characteristics. If you’re seeking maximum corrosion resistance for use in a vehicle which may use high ethanol or moderate methanol content fuels, sit for long periods of time, marine applications, Bosch is the way to go.

Chinese-based injector sets: These should be reserved for those “Go as fast as I can as cheap as I can” builds, using an aftermarket ECU, and when you have no need for emissions concerns. If you’re mainly concerned about race/higher RPM characteristics, a Chinese-based injector set will suffice. Keep in mind that you’ll only want to use them for projects that do not intend to run methanol or other fuel additives, non-marine applications, and if you’re willing to start your vehicle regularly (as you should anyway).

No matter which fuel injector set you settle on, turn to Snake Eater Performance for high-quality EFI components direct from the manufacturer. Flow-matching and lifetime warranties are included with our products. Browse through our inventory or join our mailing list for sales and other updates.